Zone Assessments for Effective Environmental Monitoring

Food safety managers face a dilemma: limited budget with an expectation (both from executives and the consumers) to build and maintain an effective food safety program. All too often, we see managers go through a full list of sampling sites in order, over and over again, instead of utilizing tools for zone assessments. Although it is a good way to confirm that all sites have been covered, it is not the best way to utilize resources.

With Presage Analytics, managers can prioritize sampling sites so that higher-priority areas are tested more frequently. At the same time, they can ensure that all areas are tested within a specified period.

What are Zone Assessments?

An important step in building a bullet-proof food safety program is conducting a zone assessment of the entire facility. Zone assessments involve dividing all production areas and more, like storage, receiving, loading docks, etc., into designated zones based on contamination risk. This process helps managers identify potential hotspots for microbial growth and allows them to develop targeted cleaning and sanitation practices.

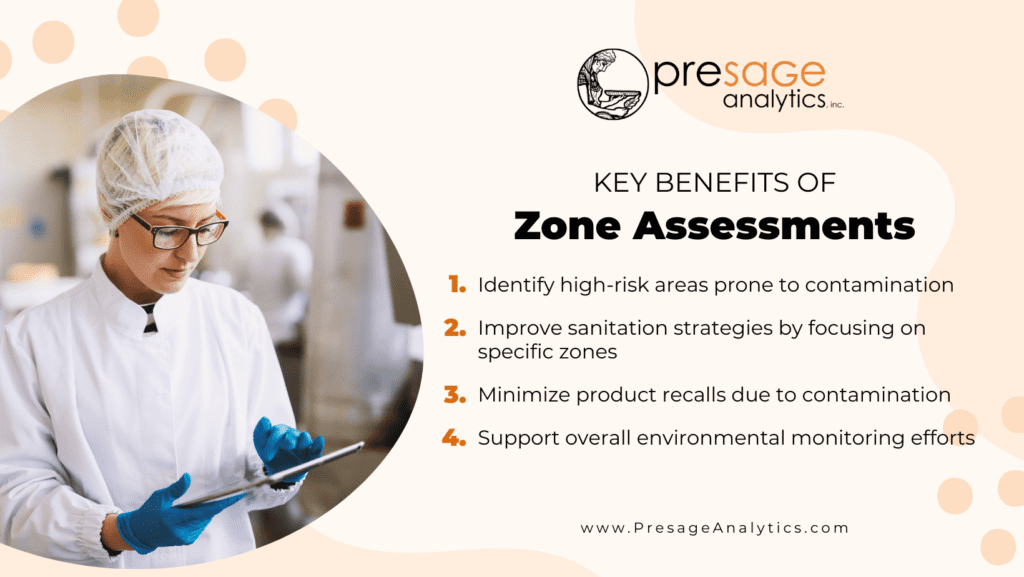

Key Benefits of Zone Assessments:

- Identify high-risk areas prone to contamination

- Improve sanitation strategies by focusing on specific zones

- Minimize product recalls due to contamination

- Support overall environmental monitoring efforts

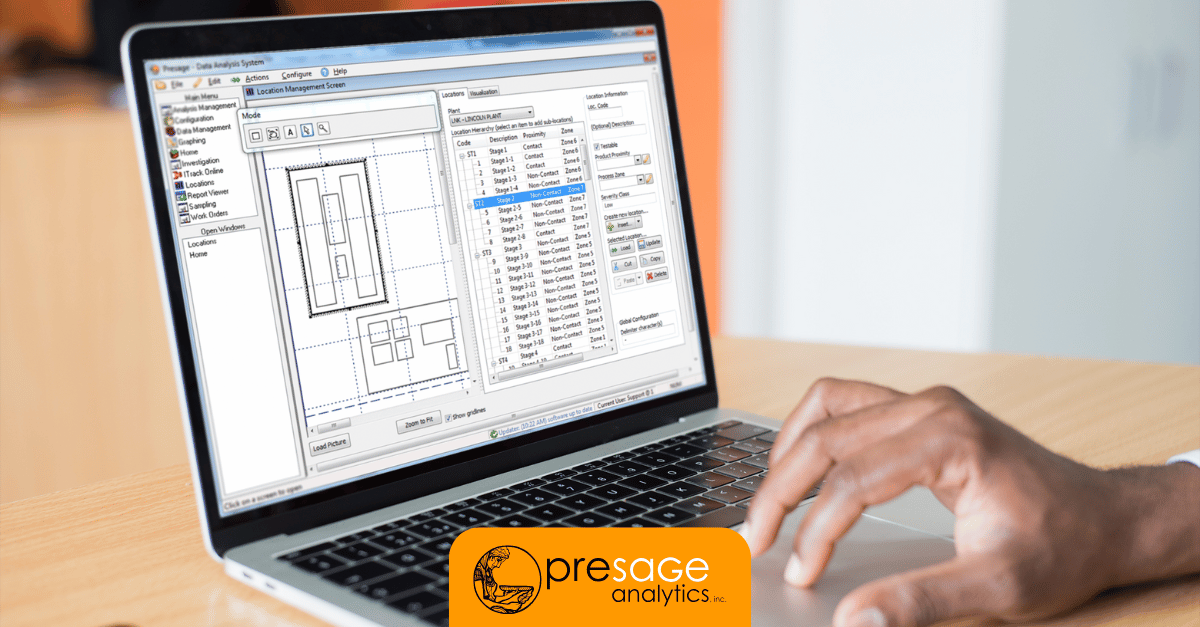

Zone Assessments using Presage Analytics

Presage has a powerful location organization system which labels each site three ways: by process zone, product proximity, and severity.

Process Zones

Process zones are areas in the facility such as receiving, packaging, chilling, or conveyor lines. Every production facility is designed with the flow of process steps in mind. Grouping sites by zones helps technicians find sampling sites quicker, and it helps managers monitor the trends for each process zone over time.

Product Proximity

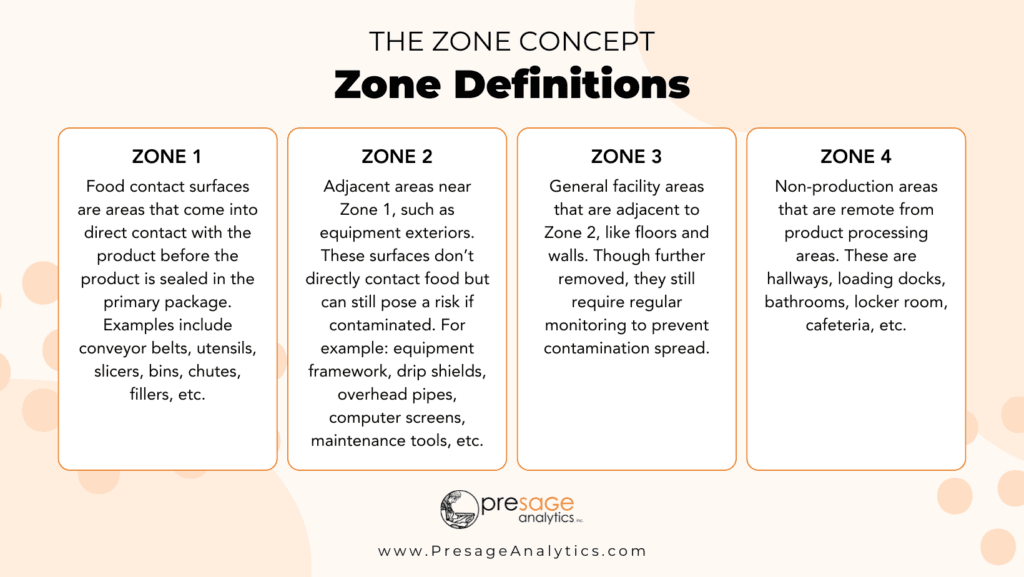

Proximities may be food contact, non-product contact, environmental and non-production – we follow The Zone Concept.

The Zone Concept – Zone Definitions:

- Zone 1: Food contact surfaces are areas that come into direct contact with the product before the product is sealed in the primary package. Examples include conveyor belts, utensils, slicers, bins, chutes, fillers, etc.

- Zone 2: Adjacent areas near Zone 1, such as equipment exteriors. These surfaces don’t directly contact food but can still pose a risk if contaminated. For example: equipment framework, drip shields, overhead pipes, computer screens, maintenance tools, etc.

- Zone 3: General facility areas that are adjacent to Zone 2, like floors and walls. Though further removed, they still require regular monitoring to prevent contamination spread.

- Zone 4: Non-production areas that are remote from product processing areas. These are hallways, loading docks, bathrooms, locker room, cafeteria, etc.

Severity

Severities identify the level of risk in contamination: high, medium, low. In Presage, severity is assigned to each process zone and product proximity combination. For example, food contact surfaces in the ready to eat processing areas of the production plant will have a high severity.

Learn how Presage can help!

To learn how Presage Analytics can help your facility conduct effective zone assessments and streamline your environmental monitoring, schedule a demo today.