Selecting the Right Equipment for Your Food Manufacturing Business

Running a successful food manufacturing business requires meticulous planning and investment in the right equipment. Choosing the appropriate machinery is crucial for ensuring efficiency, compliance with safety regulations, and maintaining the quality of your products.

1. Identify Your Production Needs

Before diving into the vast array of equipment options, take the time to understand your production requirements. Consider factors such as the volume of products, the variety of items in your portfolio, and any specific processing needs. This initial step will serve as the foundation for your equipment selection process.

2. Ensure Compliance with Food Safety Standards

Safety is paramount. Your equipment must adhere to strict industry standards and regulations to guarantee the production of safe and high-quality food products. Look for machinery that meets or exceeds guidelines set by relevant authorities to avoid potential legal issues and uphold the trust of your consumers.

3. Assess Operational Efficiency

Efficiency is the heartbeat of any successful manufacturing business. Evaluate the speed, precision, and reliability of the equipment you’re considering. Modern technology offers a range of innovative solutions designed to enhance productivity, reduce downtime, and streamline processes. Choose equipment that aligns with your production goals and contributes to the overall efficiency of your operations.

4. Consider Flexibility and Scalability

As your food manufacturing business grows, so should your equipment. Opt for machinery that offers flexibility and scalability to accommodate changes in production volume and product variety. This adaptability ensures that your business remains agile and capable of meeting evolving market demands.

5. Factor in Maintenance and Upkeep

Regular maintenance is key to extending the lifespan of your equipment and preventing unexpected breakdowns. When selecting machinery, consider the ease of maintenance and the availability of replacement parts. Look for manufacturers that provide comprehensive support and maintenance services to keep your operations running smoothly.

6. Embrace Automation for Precision

Automation plays a pivotal role in ensuring precision and consistency. Automated systems not only improve accuracy but also reduce the risk of human error. Explore equipment options with integrated automation features to enhance the overall quality and efficiency of your production processes.

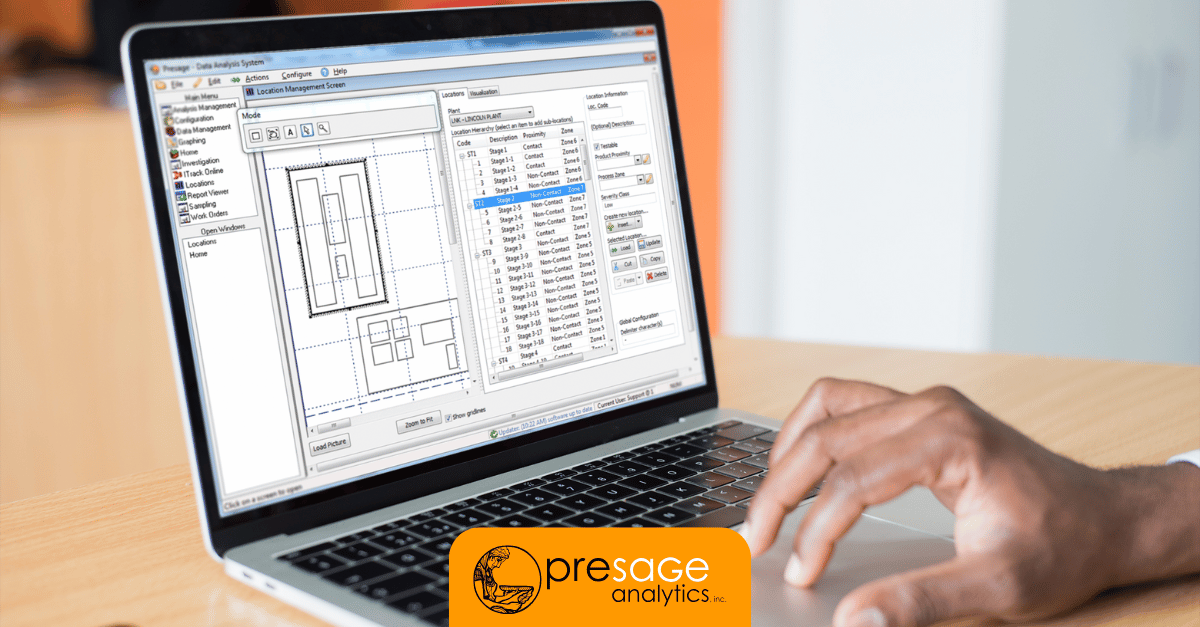

7. Leverage Data Analytics for Informed Decision-Making

Presage Analytics takes your food manufacturing business to the next level by offering cutting-edge data analytics solutions. By harnessing the power of data, you can gain valuable insights into your production processes, optimize resource utilization, and make informed decisions to drive business growth.

Schedule a Demo with Presage

To experience firsthand how Presage Analytics can revolutionize your food manufacturing operations, we invite you to schedule a personalized demo. Our innovative solutions are tailored to enhance efficiency, ensure compliance, and elevate the overall performance of your business.

In conclusion, selecting the right equipment for your food manufacturing business requires a strategic approach that encompasses safety, efficiency, flexibility, and scalability. By considering these factors and exploring the advanced capabilities offered by Presage Analytics, you can position your business for success in a competitive market. Schedule a demo today and unlock the potential of data-driven decision-making for your food manufacturing venture.