Cleaning and Sanitation in Food Processing

The cleanliness of your plant directly impact product quality, consumer safety, and regulatory compliance. Effective cleaning and sanitation prevent contamination, ensuring safe and high-quality products. Proper practices also help meet industry regulations and avoid costly fines and shutdowns.

Effective Cleaning and Sanitation Practices

Understanding the Basics

Cleaning removes visible dirt and debris, while sanitation reduces microbial load. Both are essential for a clean and safe environment. Key components of effective procedures include proper tools, techniques, and products.

Steps for Effective Cleaning and Sanitation

- Pre-cleaning: Remove visible debris and residues.

- Cleaning: Use detergents and tools to eliminate soil and residues.

- Rinsing: Remove cleaning agents and residues.

- Sanitizing: Apply appropriate sanitizers to reduce microbial load.

- Verification: Ensure that cleaning and sanitation were effective.

How to Develop a Cleaning and Sanitation Program

Assessing Your Current Processes

Start by conducting a thorough audit of existing practices. Identify areas for improvement and potential hazards.

Setting Goals and Objectives

Establish clear, achievable goals for your cleaning and sanitation program. Align these goals with regulatory standards and best practices.

Creating Sanitation Standard Operating Procedures (SSOPs)

Develop detailed SSOPs for each task. Ensure consistency and thoroughness in execution.

Training and Education

Train staff on SSOPs. Provide ongoing education and reinforcement of best practices.

Monitoring and Verification

Implement a system for regular monitoring and verification. Use tools and technology to track and document activities.

Benefits of a Robust Cleaning and Sanitation Program

- Enhancing Product Quality and Safety: A robust program reduces contamination risks and improves product shelf life. This ensures high-quality, safe products for consumers.

- Regulatory Compliance and Inspection Readiness: Meeting industry standards ensures you are prepared for inspections. A robust program helps avoid fines and shutdowns.

- Operational Efficiency and Cost Savings: Streamlined cleaning processes reduce downtime. This leads to cost savings and increased operational efficiency.

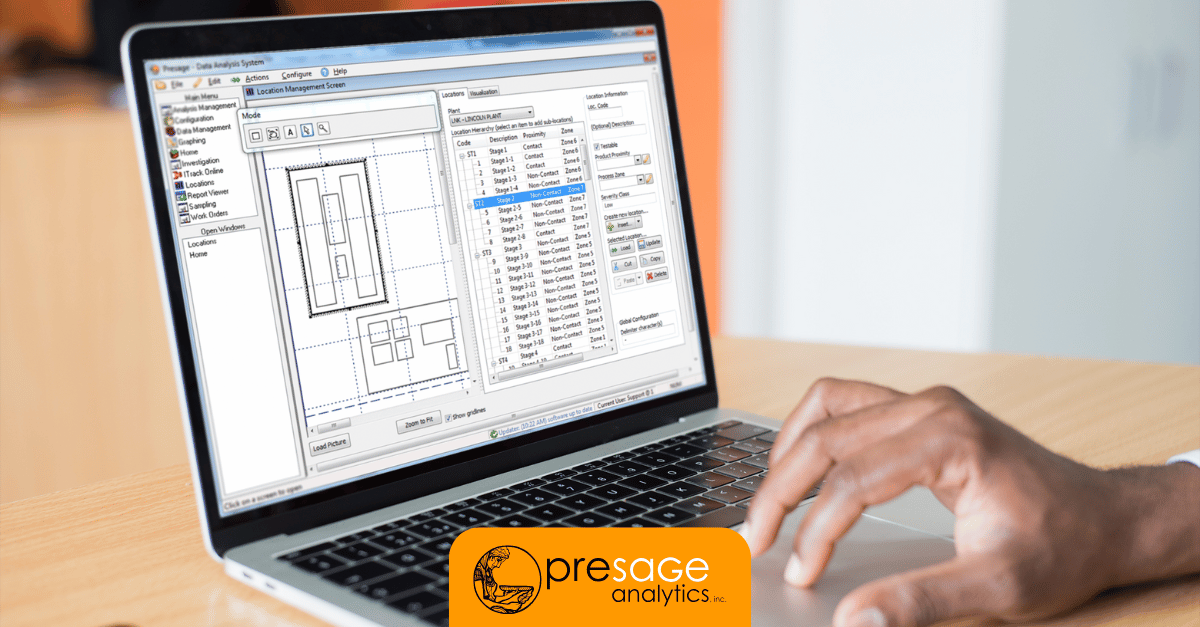

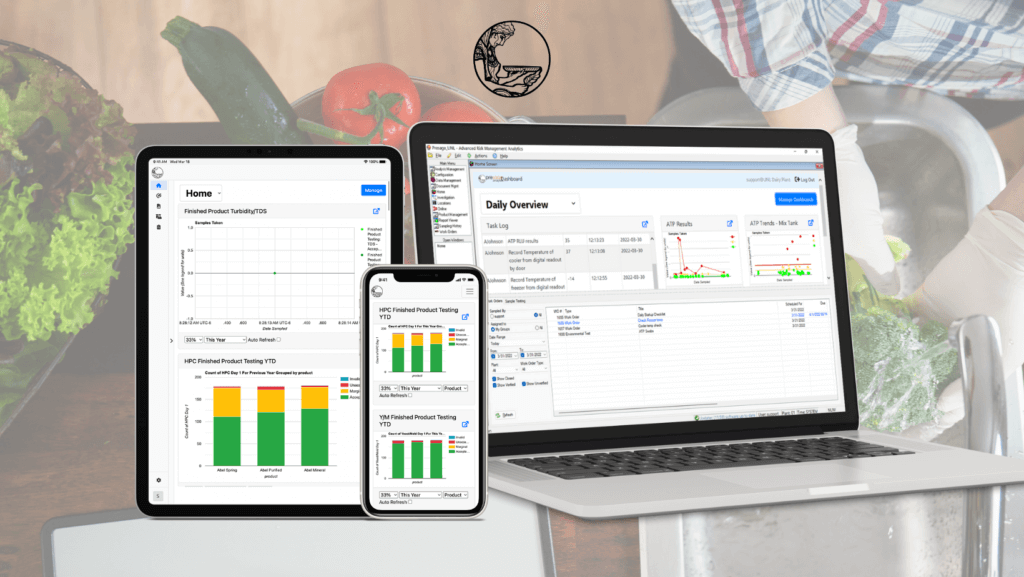

Why Choose Presage Analytics

Presage Analytics helps manage Sanitation Standard Operating Procedures, ensuring your team maintains a clean, safe, and hygienic food production environment that meets all standards and prerequisites. Our system offers easy configuration for your sanitation program, including videos and checklists for proper temperatures, durations, and task scheduling. This prevents pathogen and allergen issues in your facility.

Additional Features of Presage Analytics

- Data Collection at the Source

- Real-time Dashboards

- Trending and Charting

- Auto-generated Recurring Tasks

- Global and Plant-based Customization

- Permission-based User Groups

- Easy Data Import and Export

- Rapid Identification with Barcoding

- Small Business to Enterprise Scalability

Schedule a Demo with Presage Analytics Today

Cleaning and sanitation in food processing are vital for product quality and consumer safety. Effective practices and robust programs ensure regulatory compliance and operational efficiency. Partner with Presage Analytics to enhance your processes and maintain high standards. Schedule a demo today to learn more.