Reducing Food Waste in Food Manufacturing

The issue of waste is not only a significant economic concern but also an environmental and social one. According to recent estimates, nearly one-third of all food produced globally for human consumption is wasted each year. This staggering statistic underscores the urgent need for new approaches to reduce food waste, particularly within the manufacturing sector.

Thankfully, advancements in technology have paved the way for more efficient, sustainable practices in food production. By leveraging these tools, manufacturers can identify areas of waste within their processes and implement targeted solutions.

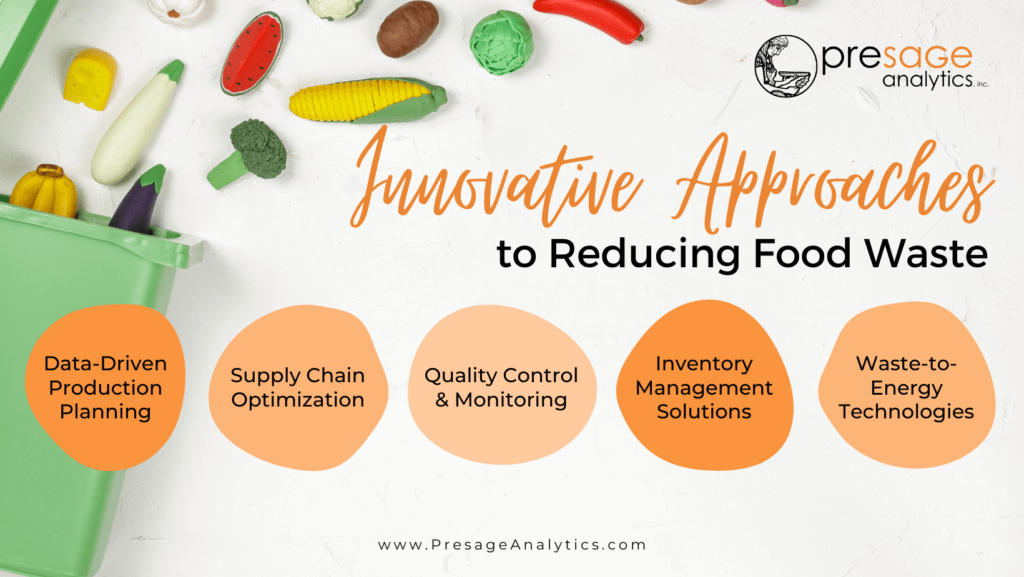

Innovated Approaches to Reducing Food Waste

- Data-driven Production Planning: One of the primary contributors to food waste is overproduction. By utilizing advanced analytics and predictive modeling, manufacturers can optimize production schedules based on real-time demand data. This enables them to produce only what is needed, reducing excess inventory and ultimately, waste.

- Supply Chain Optimization: Streamlining the supply chain is another strategy for minimizing food waste. By collaborating with suppliers and implementing just-in-time inventory practices, manufacturers can reduce the risk of perishable ingredients expiring before they are used. Additionally, establishing transparent communication channels throughout the supply chain allows for better coordination and ensures that products are delivered efficiently and on time.

- Quality Control and Monitoring: Implementing rigorous quality control measures is essential for preventing waste due to product defects or spoilage. By utilizing automated inspection systems and real-time monitoring technologies, manufacturers can identify and address issues early in the production process.

- Inventory Management Solutions: Investing in inventory management software can help manufacturers optimize inventory levels and reduce the risk of obsolete or expired products. These solutions enable better tracking of inventory turnover rates, shelf life, and stock levels, allowing companies to make data-driven decisions regarding production and purchasing.

- Waste-to-Energy Technologies: When food waste is unavoidable, implementing waste-to-energy technologies can help mitigate its environmental impact. By converting organic waste into renewable energy sources such as biogas or compost, manufacturers can minimize the amount of waste sent to landfills while simultaneously generating value from by-products.

The Presage Difference

At Presage Analytics, our team specializes in leveraging data analytics to optimize production processes, identify inefficiencies, and drive continuous improvement. By partnering with us, manufacturers can gain valuable insights into their operations and implement targeted strategies to reduce waste and increase profitability.

If you’re ready to take the next step in reducing food waste and improving the sustainability of your manufacturing processes, schedule a consultation with our sales team today. Together, we can work towards a more efficient and environmentally responsible future for the food industry. Let’s make a positive impact together.

Contact us now to schedule your demo and take the first step towards reducing food waste in your manufacturing processes.