Why Digital HACCP is the Future of Product Safety

Mistakes in food production can lead to serious consequences, from foodborne illnesses to costly recalls. Businesses must have strong food safety processes to prevent these risks. HACCP (Hazard Analysis and Critical Control Points) provides a structured approach to identifying and controlling hazards. However, traditional HACCP methods rely on manual processes that can be time-consuming and error-prone.

Digital HACCP streamlines food safety by automating monitoring, improving data accuracy, and enhancing compliance. Food businesses that switch to digital systems gain better control, faster response times, and increased transparency.

Traditional vs. Digital HACCP: What’s the Difference?

Challenges of Traditional HACCP

Traditional HACCP methods rely on paper records and manual data entry. These outdated processes create several challenges:

- Employees must manually check and record critical control points, increasing the risk of human error.

- Paper records are difficult to organize and retrieve, slowing audits and compliance reporting.

- Delayed detection of safety risks can lead to product contamination and costly recalls.

How Digital HACCP Transforms Food Safety

Digital HACCP replaces manual monitoring with sensors, software, and automated alerts. These improvements help businesses:

- Continuously track temperature, humidity, and other critical factors in real time.

- Receive instant alerts when measurements fall outside safe limits.

- Automatically store, organize, and analyze data for faster audits and trend identification.

- Improve accuracy and reduce human errors in food safety monitoring.

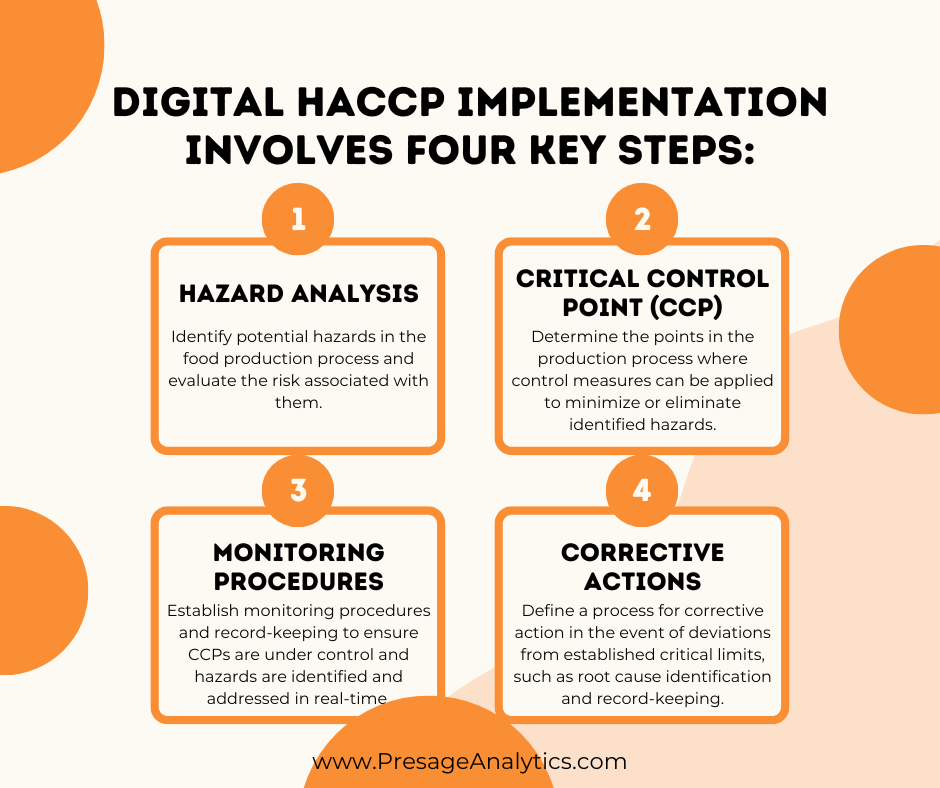

Going digital normally involves these four key steps:

- Hazard Analysis – Identify potential hazards in the production process and determine preventive measures.

- Critical Control Points (CCP) – Establish key points where hazards must be controlled to ensure food safety.

- Monitoring Procedures – Use digital sensors and software to track CCPs in real time and detect deviations.

- Corrective Actions – Implement automatic alerts and corrective measures when safety thresholds are breached.

Switching to a digital process gives businesses the tools they need to prevent hazards before they become major problems.

Better Tracking, Better Transparency

Stronger Traceability and Faster Response Times

Food safety incidents require immediate action. Digital HACCP systems track every step of production and provide instant access to historical data. This improves traceability and helps businesses respond faster to potential hazards.

Simplified Compliance with Food Safety Regulations

Regulatory agencies require detailed food safety records. Digital HACCP systems automatically log and organize critical data, making audits easier and ensuring compliance with industry standards.

Lower Risk of Recalls and Brand Damage

Product recalls cost businesses millions of dollars and damage consumer trust. Digital HACCP minimizes recall risks by detecting problems early and ensuring accurate record-keeping. When issues arise, businesses can act quickly to protect consumers and their reputation.

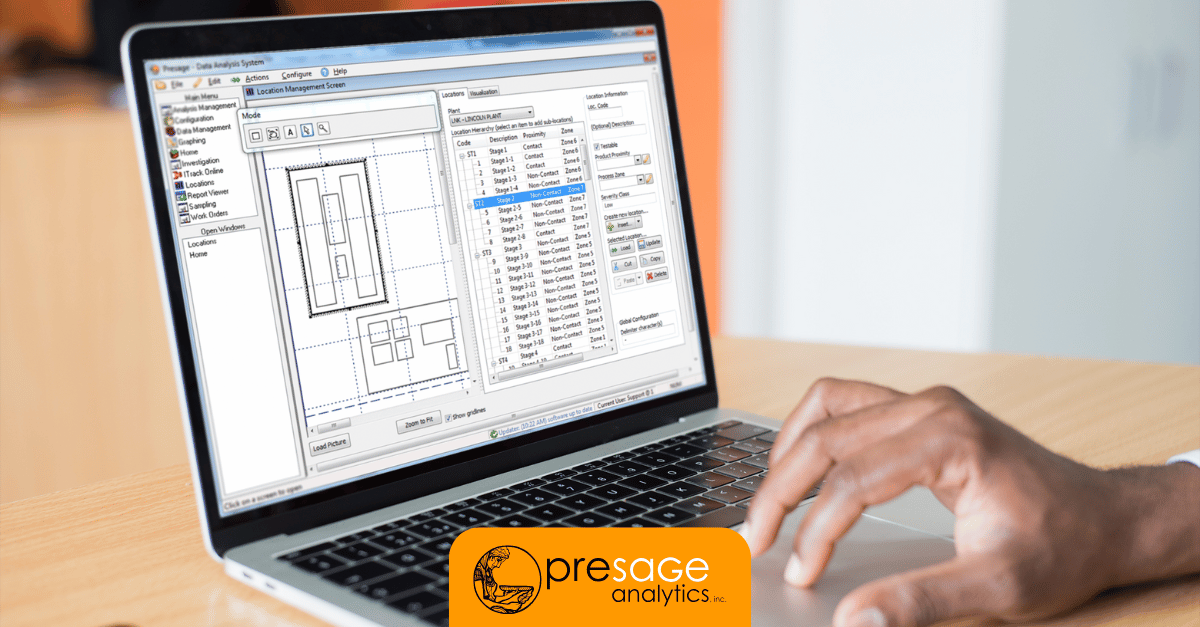

How Presage Analytics Powers Digital HACCP

Presage Analytics provides a comprehensive digital HACCP solution designed for food and beverage businesses. Our software automates critical safety processes, helping companies:

- Monitor production environments in real time.

- Reduce errors with automated alerts and digital record-keeping.

- Streamline compliance with built-in regulatory reporting tools.

- Improve efficiency by eliminating paper-based processes.

With Presage Analytics, businesses can ensure food safety, maintain compliance, and operate more efficiently. Schedule a demo with Presage Analytics today and take the next step in improving your food safety program.