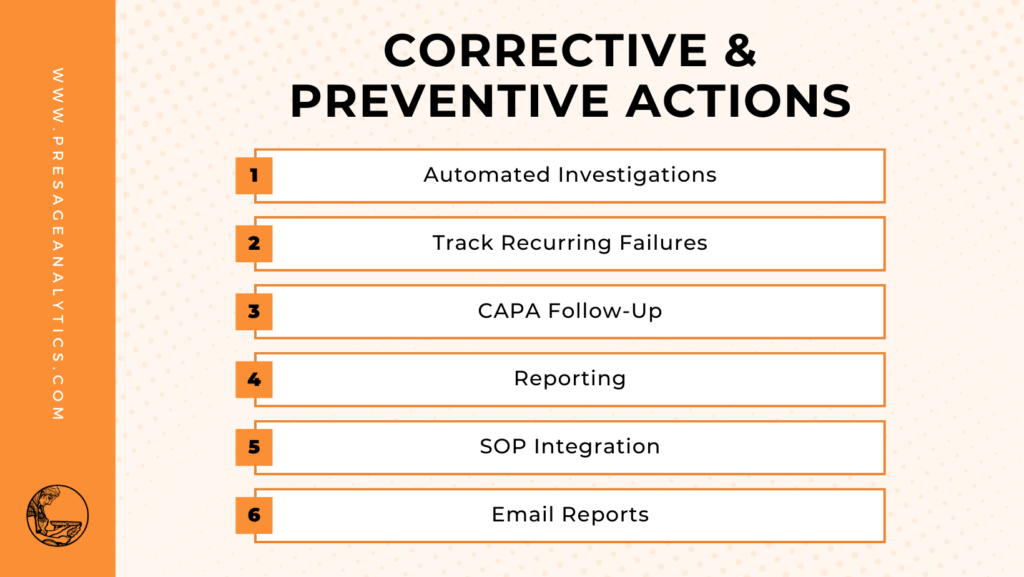

Corrective and Preventive Actions: Ensuring Quality Control with Automated Investigations

Advancing technology reshapes business operations, making product quality crucial. Corrective and preventive actions (CAPA) are vital in maintaining standards in the food and beverage sector. Presage Analytics prioritizes efficiency, automatically triggering investigations for failed results and addressing potential issues proactively.

Automated Investigations for Proactive Quality Control

Presage Analytics empowers your plant by automatically initiating investigations when deviations from the norm are detected. This approach ensures that potential problems are identified in real-time, preventing them from affecting the overall quality of your products. By automating this aspect, Presage allows for swift responses, minimizing the risk of subpar products reaching consumers.

Tracking Recurring Failures for Continuous Improvement

In addition, Presage’s software is its ability to track recurring failures. By analyzing patterns and trends in the data, the system identifies potential areas for improvement in your production processes. This approach facilitates continuous improvement, helping your plant adapt to changing circumstances. With Presage Analytics, you can break the cycle of recurring failures and implement lasting solutions.

Effortless CAPA Follow-Up Built-In

Presage understands that the effectiveness of CAPAs lies not only in their implementation but also in their follow-up. The software integrates CAPA follow-up into the investigation process, ensuring that corrective and preventive actions are not only identified but also implemented and monitored over time. This built-in functionality streamlines the entire process, making it more efficient and reliable.

Simple and Accessible Reporting

Presage Analytics takes the complexity out of reporting by providing simple, easily accessible summaries of CAPAs. These reports are designed to be user-friendly, allowing stakeholders at all levels of your organization to grasp the status of investigations and the corresponding actions being taken. Whether you are a quality control manager or a production team member, Presage ensures that everyone has access to the information they need to contribute to the success of your quality control initiatives.

Integration with Standard Operating Procedures

Presage Analytics doesn’t just offer a standalone solution; it seamlessly integrates with your existing Standard Operating Procedures (SOPs). This ensures that corrective and preventive actions are documented in accordance with established protocols, maintaining compliance and facilitating a smooth transition for your team. The software becomes a valuable asset, enhancing your existing processes rather than disrupting them.

Stay Informed with Email Reports

Presage Analytics goes the extra mile to keep you informed. Receive regular email reports summarizing all CAPAs, allowing you to stay updated on the status of investigations without having to navigate through complex systems. This proactive approach to communication ensures that you are always in the loop, ready to make informed decisions to uphold the quality and safety of your products.

Take the Next Step: Schedule a Demo with Presage

For those exploring inventory management software and seeking to elevate their quality control processes, Presage Analytics is the solution you’ve been looking for. To experience the full range of benefits and witness how automated investigations and CAPA follow-ups can revolutionize your approach, schedule a demo with our dedicated sales team.

In conclusion, Presage Analytics is not just a software solution; it’s a strategic partner in your journey towards enhanced quality control and safety in the food and beverage industry. With automated investigations, proactive CAPAs, and user-friendly reporting, Presage is shaping the future of quality assurance. Schedule a demo today and empower your plant with the tools it needs to thrive in an ever-evolving market.