Enhancing Manufacturing Processes with Intelligent Features

With stringent regulations, rising consumer expectations, and the need for efficiency, companies are turning to advanced solutions to streamline their manufacturing processes. Presage Analytics is designed to revolutionize manufacturing processes and elevate the standards of food and beverage safety and quality assurance.

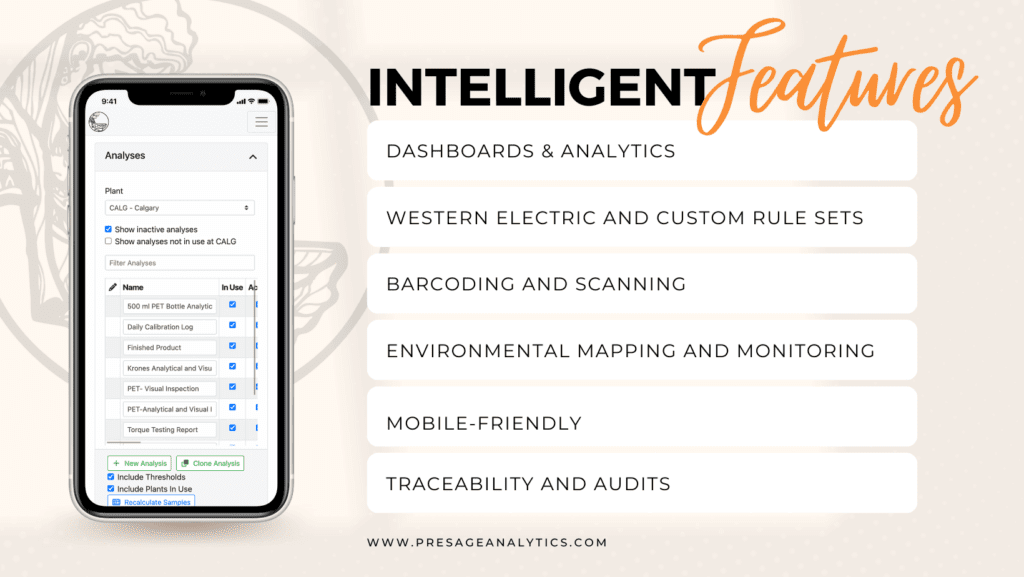

Dashboards & Analytics: A Clear Insight into Your Operations

Presage Analytics empowers manufacturers with intuitive dashboards and robust analytics tools, providing a real-time overview of the entire manufacturing process. Our comprehensive dashboards offer a visual representation of key performance indicators, allowing you to make informed decisions promptly. This feature is instrumental in identifying trends, analyzing production data, and optimizing manufacturing processes for enhanced efficiency.

Western Electric and Custom Rule Sets: Tailoring to Your Unique Requirements

Presage Analytics stands out by offering both Western Electric and Custom Rule Sets, ensuring a tailored approach to quality assurance. The incorporation of Western Electric rules enables the detection of subtle variations in the manufacturing process, ensuring that deviations from the norm are promptly identified. Moreover, the flexibility of custom rule sets allows companies to adapt the software to their unique specifications, aligning with the diverse requirements of the food and beverage industry.

Barcoding and Scanning: Streamlining Operations for Precision

Efficiency is key in manufacturing processes, and Presage Analytics understands the importance of seamless operations. The inclusion of barcoding and scanning capabilities not only reduces the likelihood of errors but also enhances traceability. With Presage Analytics, you can effortlessly track raw materials, monitor production stages, and manage inventory with precision, ultimately contributing to a more streamlined and error-free manufacturing process.

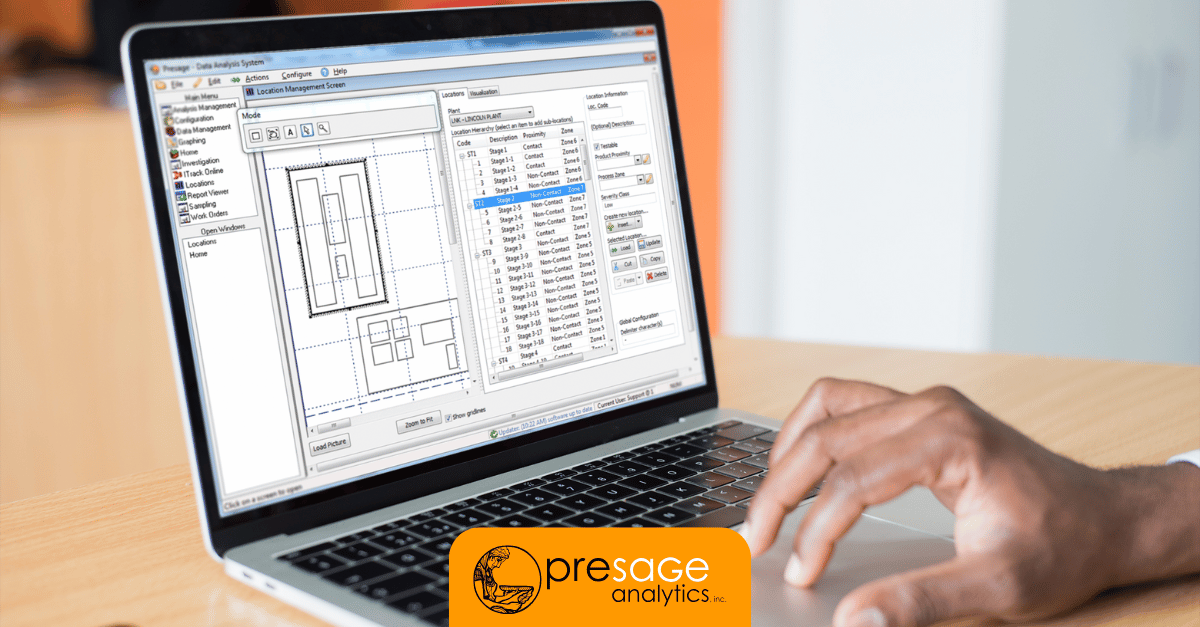

Environmental Mapping and Monitoring: Ensuring Optimal Conditions

Presage Analytics goes beyond traditional quality assurance by offering environmental mapping and monitoring features. This ensures that the manufacturing environment remains optimal for production. By continuously monitoring factors such as temperature, humidity, and other critical parameters, the software mitigates the risk of quality issues arising from unfavorable conditions. This proactive approach to environmental control is a game-changer in maintaining product integrity.

Mobile-Friendly: Empowering On-the-Go Decision-Making

In today’s fast-paced manufacturing environment, access to real-time data is essential. Presage Analytics recognizes this need by providing a mobile-friendly web app, Presage Web, allowing key stakeholders to access critical information from anywhere. Whether on the production floor, in a meeting, or off-site, manufacturers can stay connected and make informed decisions on the go, contributing to agility and responsiveness.

Traceability and Audits: Upholding Transparency and Compliance

Presage Analytics places a strong emphasis on traceability and audits, essential components of quality assurance in food and beverage manufacturing. The software enables companies to trace products through every stage of the production process, facilitating quick and accurate recalls if necessary. Additionally, the audit trail functionality ensures compliance with regulatory requirements, giving manufacturers the confidence that their processes align with industry standards.

Schedule a Demo with the Presage Team

Presage Analytics emerges as a comprehensive solution for food and beverage manufacturers seeking to elevate their quality assurance and safety practices. By focusing on intelligent features the software addresses the diverse needs of the industry. To truly grasp the potential of Presage Analytics, we invite you to schedule a demo today. Experience firsthand how this innovative software can optimize your manufacturing processes, ensuring a future of excellence in food and beverage production. Your journey towards enhanced quality and efficiency starts here.