Enhancing Operational Efficiency: A Deep Dive into Presage Analytics

Efficiency isn’t just a buzzword anymore—it’s integral if you want your business to succeed. Every aspect of operations hinges on how smoothly and effectively processes are executed.

Operational efficiency isn’t just about getting things done; it’s about getting them done right, in the most streamlined and effective manner possible. It involves optimizing resources, minimizing waste, and maximizing output without compromising on safety or quality.

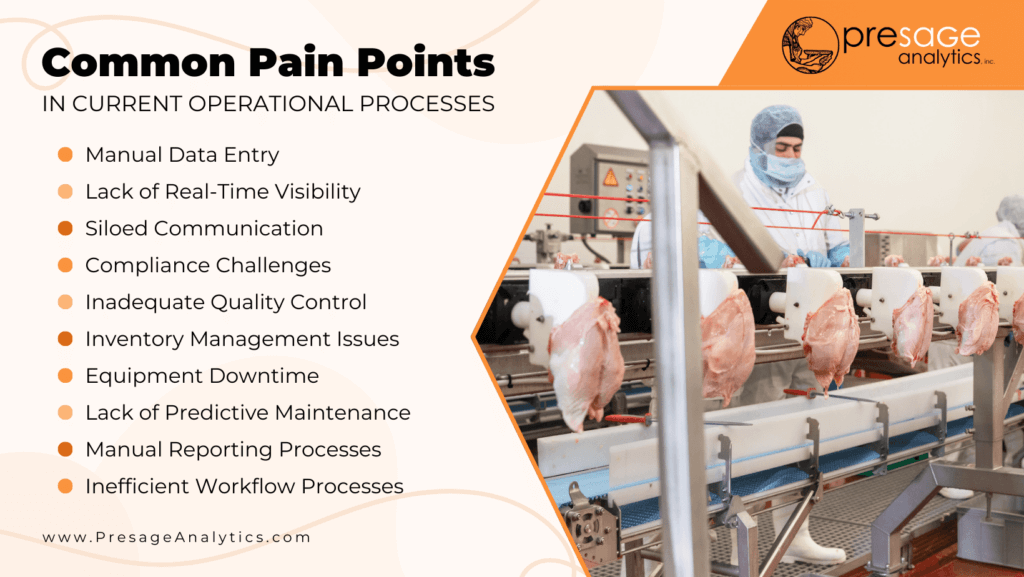

Identifying Common Pain Points in Current Operational Processes

Across the industry, processing plants face a myriad of challenges that affect efficiency. From manual record-keeping to outdated software systems, these obstacles not only slow down operations but also increase the risk of errors and compliance issues.

- Manual Data Entry: Relying on manual data entry is not only time-consuming but also prone to errors, leading to discrepancies in records and inefficient workflows.

- Lack of Real-Time Visibility: Without real-time visibility into operations, processing plants struggle to identify and address issues promptly, resulting in delays and disruptions.

- Siloed Communication: Inefficient communication channels between departments can lead to miscommunication, duplication of efforts, and a lack of coordination, hindering overall efficiency.

- Compliance Challenges: Meeting regulatory requirements is a constant challenge for processing plants, with manual compliance tracking often leading to oversights and compliance gaps.

- Inadequate Quality Control: Without robust quality control measures in place, processing plants risk producing subpar products, leading to customer dissatisfaction and potential recalls.

- Inventory Management Issues: Poor inventory management practices, such as inaccurate tracking or overstocking, can result in waste, increased storage costs, and production delays.

- Equipment Downtime: Unplanned equipment downtime can significantly disrupt production schedules, leading to delays, increased costs, and decreased overall efficiency.

- Lack of Predictive Maintenance: Without predictive maintenance strategies in place, processing plants are vulnerable to unexpected equipment failures, leading to costly repairs and downtime.

- Manual Reporting Processes: Manual reporting processes are not only time-consuming but also prone to errors, making it difficult for management to make informed decisions based on accurate data.

- Inefficient Workflow Processes: Inefficient workflow processes, such as redundant tasks or unnecessary approval chains, can slow down operations and decrease overall productivity.

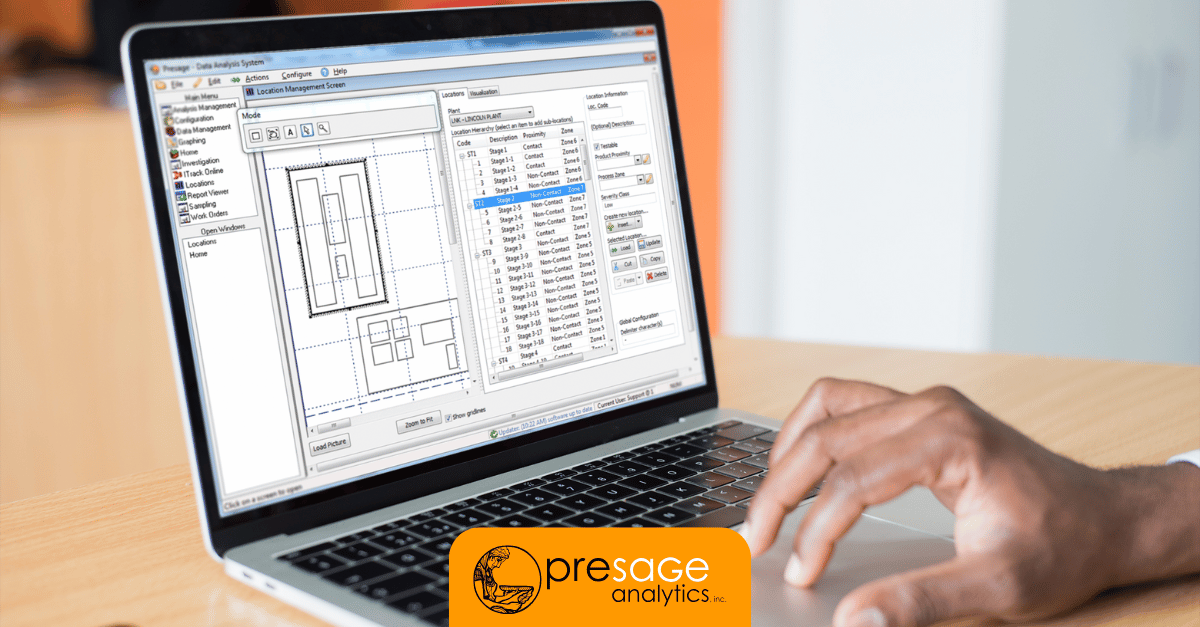

An Overview of Presage Analytics

With its advanced features and intuitive interface, Presage Analytics empowers plants to streamline their operations, enhance safety protocols, and elevate product quality. Presage Analytics tackles the most pressing challenges faced by processing plants head-on. By automating routine tasks, providing real-time insights, and facilitating seamless communication across departments, Presage revolutionizes the way plants operate, paving the way for unprecedented efficiency and productivity.

Examining the Tangible Benefits of Operational Efficiency

With Presage Analytics, the benefits extend far beyond mere efficiency gains. Increased productivity means more output with fewer resources, translating into tangible cost savings and improved profitability. Moreover, by ensuring compliance with regulatory standards, Presage Analytics mitigates the risk of costly fines and recalls, safeguarding both reputation and bottom line.

But the journey doesn’t end here. Presage Analytics is committed to ongoing innovation, constantly refining and enhancing its software to meet the evolving needs of the industry. From predictive maintenance to machine learning algorithms, the future holds boundless possibilities for further optimizing food processing operations.

Embracing Technology for Sustainable Growth and Resilience

By adopting Presage Analytics, processing plants can future-proof their operations, fortifying themselves against unforeseen challenges and positioning themselves for sustainable growth and resilience.

If you’re ready to take your processing plant to new heights of operational efficiency, look no further than Presage Analytics. Schedule a demo today and discover firsthand how Presage Analytics can revolutionize your operations, ensuring safety, quality, and unparalleled success.