Harnessing Predictive Maintenance

With constantly evolving regulations and consumer expectations, maintaining operational efficiency while upholding rigorous standards can be a daunting task. However, proactive measures like predictive maintenance have emerged as game-changers in the industry.

Predictive maintenance, as the name suggests, revolves around foreseeing potential equipment failures before they occur. By leveraging data analytics, Presage Analytics empowers plants to predict and prevent breakdowns, thereby averting costly production halts and ensuring uninterrupted operations.

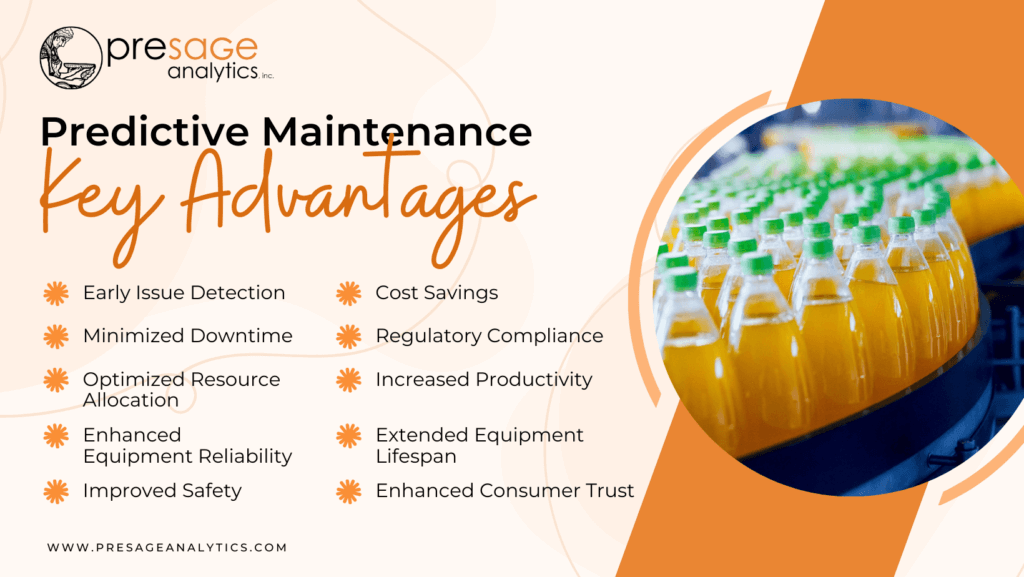

Key Advantages of Predictive Maintenance

- Early Issue Detection: Enables early detection of equipment issues, allowing for proactive interventions before failures occur.

- Minimized Downtime: Anticipates potential breakdowns, minimizing unplanned downtime and ensuring uninterrupted production.

- Optimized Resource Allocation: Prioritizes maintenance activities based on criticality, maximizing operational efficiency.

- Enhanced Equipment Reliability: Improves the reliability of critical equipment, ensuring consistent performance.

- Improved Safety: Maintains equipment in optimal condition, mitigating contamination risks and upholding hygiene standards.

- Cost Savings: Reduces the need for costly emergency repairs and replacements, resulting in significant cost savings.

- Regulatory Compliance: Aligns with regulatory requirements, reducing the risk of fines and penalties.

- Increased Productivity: Minimizes production losses and downtime, increasing overall productivity.

- Extended Equipment Lifespan: Prolongs the lifespan of equipment, maximizing return on investment.

- Enhanced Consumer Trust: Consistently delivers safe and high-quality products, fostering consumer trust and loyalty.

Schedule a Demo Today

Presage Analytics offers a holistic approach to food and beverage safety, combining predictive maintenance with advanced analytics to minimize downtime and ensure compliance. To experience the transformative power of predictive maintenance firsthand, schedule a demo with our dedicated sales team. Our experts will guide you through our suite of solutions, tailored to address your specific challenges and objectives.