Sample Traceability with Presage Analytics

Updated 11/29/2023

If you could eliminate all risk associated with storing or preserving your samples, and have the assurance that they have not been altered since they were collected, wouldn’t that be great? Sample traceability enables you to track the history, location, and movement of a sample from the time it is produced until it reaches its final destination. This is especially important in the food and beverage industry, as it helps to guarantee the safety, quality, and authenticity of the products.

With Presage Analytics, you can know exactly what was tested and recorded on each sample – whether the sample was taken last week or last year. By utilizing our modified data indicator and Change Log, you can be sure those records haven’t changed since they were tested. If they have been changed, Presage will tell you who changed them, how they were changed, and when.

What is Sample Traceability?

In the intricate web of the food and beverage industry, ensuring product safety and quality is paramount. Sample traceability stands as a crucial component in this pursuit, serving as a systematic method to track and manage samples throughout the production and distribution processes.

Understanding Sample Traceability

Sample traceability involves the meticulous documentation and monitoring of samples at various stages of the production chain. This encompasses raw materials, intermediate products, and the final goods that reach consumers’ hands. The goal is to establish a comprehensive record of each sample’s journey, from its origin to its ultimate destination.

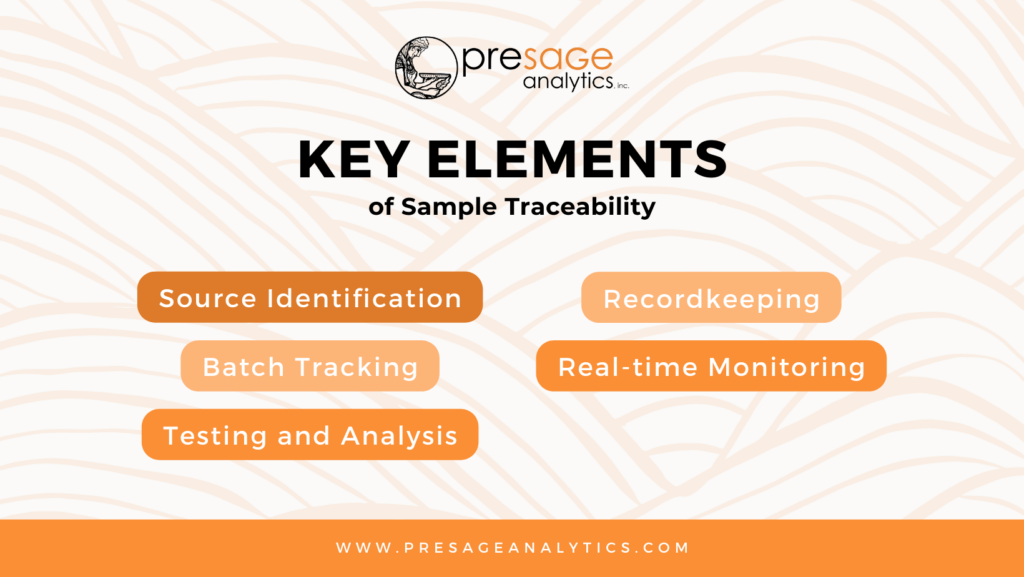

Key Elements of Sample Traceability in the Food and Beverage Industry

- Source Identification: Traceability starts at the source. Each sample is linked to its specific origin, detailing information such as supplier details, production date, and batch numbers.

- Batch Tracking: Samples are often grouped into batches during production. Batch tracking allows for the association of specific tests and results with a particular production run, facilitating targeted quality control measures.

- Testing and Analysis: Throughout the production process, samples undergo various tests and analyses to ensure compliance with quality standards. These results are integral to the traceability process, providing insights into the safety and quality of the product.

- Recordkeeping: Accurate and detailed recordkeeping is central to sample traceability. This involves maintaining a comprehensive database that includes information on sample characteristics, test results, and any deviations from established quality parameters.

- Real-time Monitoring: With advancements in technology, real-time monitoring of samples has become more achievable. This allows for immediate intervention in case of any anomalies and enhances the ability to respond swiftly to quality issues.

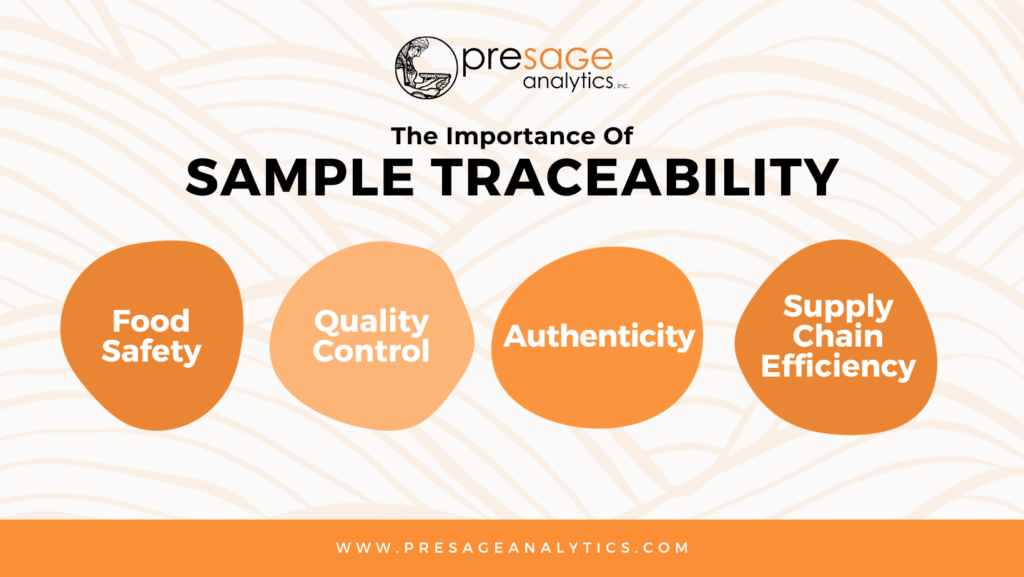

Why Is Sample Traceability Important?

- Food Safety – Identify and recall unsafe or contaminated foods from the market, to protect consumers and prevent illnesses and potential outbreaks. Presage Analytics helps you locate the source of the contamination, allowing for corrective action to be taken to prevent future incidents.

- Quality Control – Ensure that products meet quality standards, such as those set by regulatory bodies or industry standards. With Presage Analytics, you can identify and correct problems with production processes, ensuring that products are consistent and high quality every time.

- Authenticity – Verify the origin and authenticity of products to allow consumers to make informed choices about the products they purchase. Presage helps to prevent fraud and mislabeling, which can be a significant problem in the food and beverage industry.

- Supply Chain Efficiency – Improve the efficiency of the supply chain by allowing for the rapid identification and resolution of any issues that may arise. Presage Analytics can help to reduce waste and improve the overall efficiency of the food and beverage industry.

There are several ways that food traceability can be implemented, such as barcode scanning, RFIDs and manual tracking – Presage Analytics uses barcode technology. With a simple scan, information regarding a sample is at your fingertips, ensuring that you always have easy access to the information you need to ensure the safety and quality of your product.

Schedule A Demo

It is essential that food companies have traceability systems in place to protect consumers and maintain the integrity of their products. Presage Analytics has worked hard to change the way you manage your samples—and it can change the way you manage your plants, too. Let’s schedule a demo and go over the ways Presage Analytics can help improve the safety of your product, plant and consumers.