Behind the Scenes: Food Manufacturing

If you’ve ever wondered about the intricate processes that ensure the safety and quality of the food on your plate, you’re in the right place. Food manufacturing is a complex and highly regulated industry where precision and quality assurance are paramount. In this blog post, we’ll take you on a virtual tour behind the scenes of a food manufacturing facility to shed light on the essential steps that guarantee the food on your table is safe and delicious.

Behind the Scenes of a Food Manufacturing Facility

From Farm to Factory

The journey of food begins long before it reaches the manufacturing facility. Farms and suppliers play a vital role in providing raw materials, such as fruits, vegetables, meats, and grains. These ingredients undergo rigorous inspections to ensure they meet the highest quality standards.

Ingredients Inspection

Upon arrival at the facility, ingredients go through a meticulous inspection process. This step is essential to identify any contaminants, such as foreign objects, chemicals, or microbial growth. Food manufacturing facilities utilize advanced technology and equipment to identify and remove any imperfections in the ingredients, guaranteeing the safety and quality of the final product.

Quality Assurance Through Recipe Formulation

Recipes in food manufacturing are not just a list of ingredients and instructions; they are carefully crafted formulas that guarantee taste consistency and product quality. These recipes, combined with cutting-edge software, ensure that the final product meets predefined standards.

Production and Processing

The heart of a food manufacturing facility is the production line. Here, automation and technology work hand in hand to prepare, mix, cook, and package the food. This high level of automation minimizes the risk of human error and ensures consistency in the product. But it doesn’t stop there; food safety experts continually monitor and supervise the production line to ensure it adheres to stringent safety and quality standards.

Quality Control and Testing

A crucial part of food manufacturing is quality control and testing. Samples from the production line are regularly collected and analyzed to ensure they meet the predetermined specifications. This includes sensory evaluation, chemical analysis, and microbiological testing. Any deviations from the established criteria prompt immediate corrective action to prevent substandard products from reaching consumers.

Packaging and Labeling

Packaging is not just about aesthetics; it plays a pivotal role in food safety and quality assurance. Packaging ensures the product’s integrity, extends its shelf life, and prevents contamination. Labeling, on the other hand, provides consumers with critical information, such as nutritional content, ingredient lists, and allergen warnings. It’s essential that both packaging and labeling adhere to industry standards and regulations.

Storage and Distribution

Once the food product is prepared and packaged, it enters the storage phase. Temperature control is critical during storage to prevent spoilage and maintain product quality. Distribution follows, with the food products carefully transported to retailers, restaurants, or consumers.

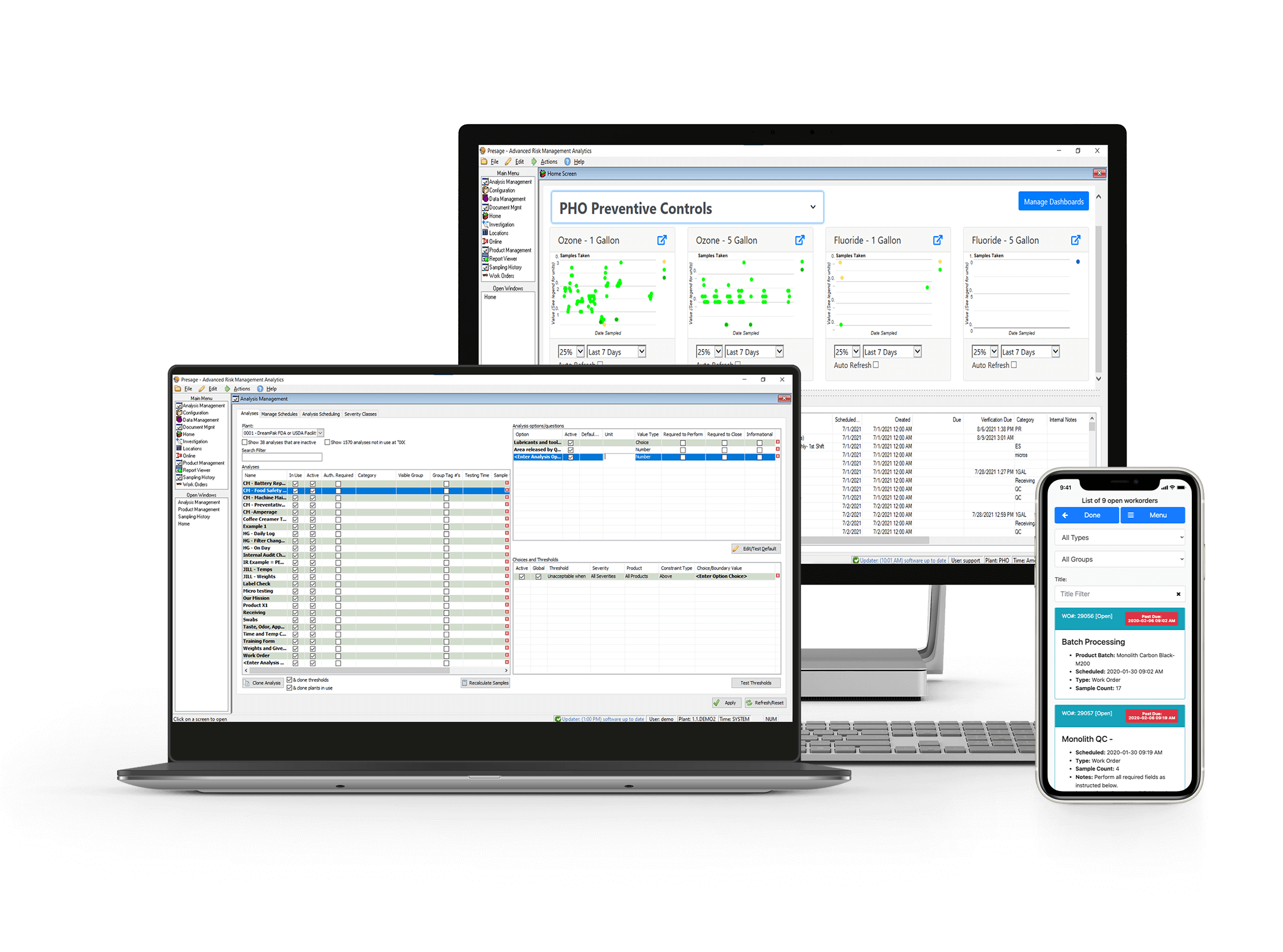

The Role of Presage Analytics

In today’s dynamic and highly regulated food manufacturing industry, technology is a game-changer. Food and beverage safety and quality assurance software, such as that provided by Presage Analytics, is essential. These solutions streamline and automate processes, making it easier for food manufacturers to meet and exceed industry standards. With Presage Analytics, you can:

- Ensure Compliance: Stay up-to-date with changing regulations and ensure your facility complies with industry standards.

- Streamline Quality Control: Automate quality control processes to minimize human error and enhance consistency.

- Monitor Supply Chain: Keep track of your supply chain and maintain transparency from farm to factory to the end consumer.

- Data-Driven Decision-Making: Utilize data analytics to make informed decisions that can enhance product quality and safety.

To learn more, schedule a demo with us today and take the first step toward elevating your food manufacturing process. Your journey to better food safety and quality assurance begins here.