Enhancing Food Safety with Real-Time Monitoring and Analytics

With consumers becoming increasingly more health-conscious, and regulatory bodies imposing stricter standards, manufacturers must stay ahead of the curve. This is where real-time monitoring and analytics come into play, with Presage Analytics is leading the charge.

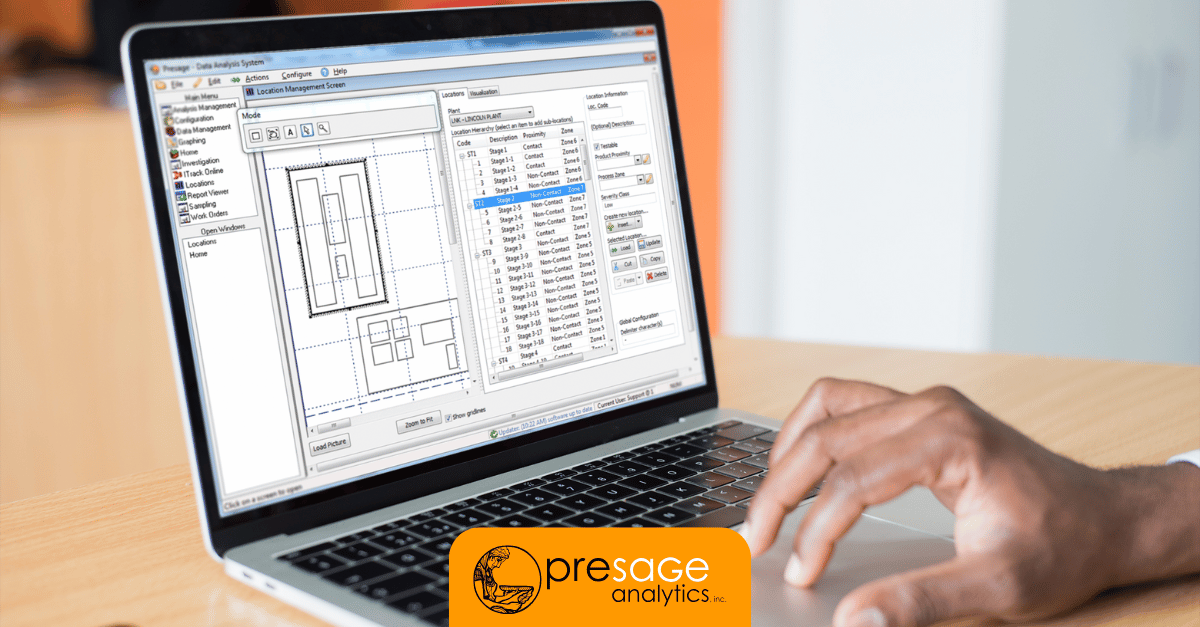

1. Dashboards & Analytics

With Presage, the vital information you need is front-and-center. Build the charts and graphs you need with just a few clicks. Dashboards can be configured for an individual, a plant, or even the whole organization. With the auto-refresh feature, you can display Presage data on a heads-up display on the plant floor, and ensure everyone knows the current status of critical control points.

If you need to dig deeper into data analytics, Presage’s suite of reports provides many options for parsing raw data into useful metrics. Reports can be set up as subscriptions, ensuring you get the key performance indicators you need, in your inbox, when you need them.

2. SPC & Control Charts

Quality is not only about ensuring your product is well-made and safe, it’s also about continually improving the consistency and efficiency of your process. Presage includes built-in Statistical Process Control using the industry-standard Western Electric ruleset, and also provides the flexibility to create your own custom rules based either on non-conformances over time, or non-conformance counts within a given set of data.

Presage can provide instant feedback when your process is trending out-of-control, even when you are well within conformance standards. You can adjust your process at the first sign of trouble, avoiding costly downtime, rework or recalls. SPC is also important as a retrospective tool. Using the Control Chart in Presage, you can evaluate how changes to your process affected outcomes, and hone in on precise process adjustments to ensure consistency and quality.

3. Sanitation Procedures

Sanitation Standard Operating Procedures make sure that your team runs a clean, safe, and hygienic food production program that meets necessary standards and prerequisites with adequate monitoring and documentation. Easily configure your sanitation program, including videos and checklists for proper temperatures, durations, and task scheduling, to prevent your facility from running into pathogen and allergen issues. Ensure your 3rd party sanitation teams’ cleaning is verified every time.

4. Corrective & Preventive Maintenance

Investigations in your plant can be automatically triggered for any failed results. These tools help identify and address issues, track recurring failures, and ensure consistent quality control. Investigations contain simple, easily accessible and reportable CAPA follow-up built-in. Summarize all of your CAPAs in simple-to-read reports delivered to your email. Ensure you’ve properly documented any corrective and preventive actions according to your Standard Operating Procedures.

5. Data-Driven Decision-Making

Presage Analytics Software doesn’t just collect data; it transforms it into actionable insights. Real-time analytics allow you to make informed decisions swiftly. Whether it’s adjusting a recipe, fine-tuning production parameters, or responding to changing market demands, having access to real-time data empowers you to stay agile in a competitive industry.

Real-time Monitoring Matters

The benefits are clear: improved quality control, enhanced safety protocols, optimal resource management, preventive maintenance, and data-driven decision-making. Presage Analytics Software is your partner in achieving these benefits and ensuring your products meet the highest standards of quality and safety.

To experience the power of Presage Analytics Software firsthand, schedule a demo with our sales team today. Don’t wait until an issue arises; take proactive steps to enhance your food processing operations with real-time monitoring and analytics. Your brand’s reputation and the safety of your customers are at stake, and Presage Analytics is here to help you protect them.