Statistical Process Control: Enhancing Food Safety with Presage Analytics

Quality in the food and beverage industry goes beyond just ensuring products are well-made and safe. It’s about continuously refining processes to enhance consistency and efficiency. At Presage Analytics, we understand the pivotal role of maintaining the highest standards in food safety. Our platform not only keeps you compliant with the latest regulations but also simplifies the complex task of monitoring and improving compliance through intelligent tools and features.

One such indispensable tool is Statistical Process Control (SPC), integrated seamlessly into Presage Analytics using the industry-standard Western Electric (WECO) rules. Let’s delve into what SPC and WECO entail and how they contribute to bolstering food safety measures.

Understanding SPC and WECO Rules

SPC is a method grounded in statistical analysis, employed to monitor and manage processes effectively. It enables businesses to detect variations in production processes promptly, thereby averting potential quality issues before they escalate.

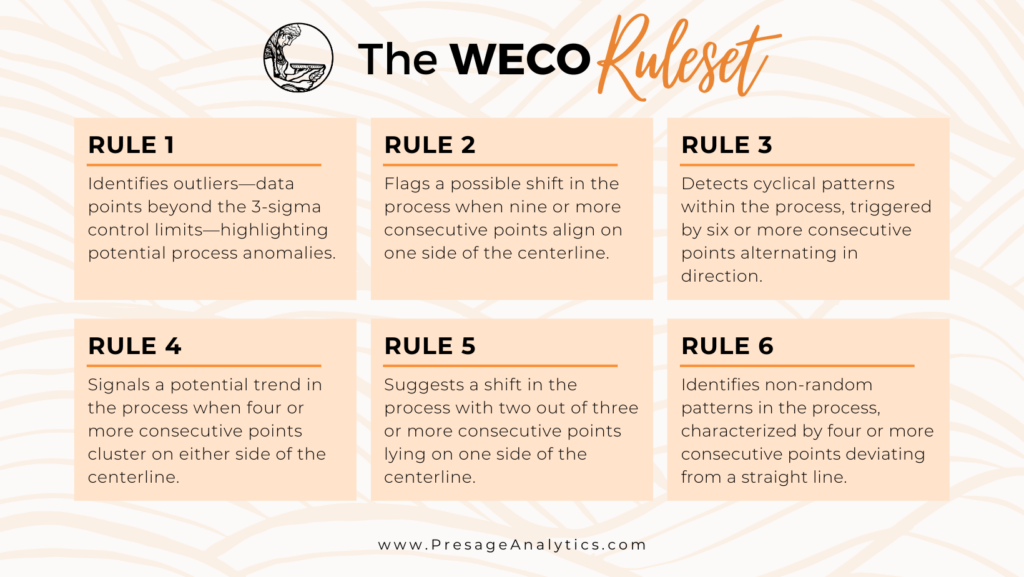

The WECO ruleset serves as a beacon in this endeavor, comprising six fundamental rules tailored to identify distinct patterns in data that may signify deviations from acceptable process norms:

- Rule 1: Identifies outliers—data points beyond the 3-sigma control limits—highlighting potential process anomalies.

- Rule 2: Flags a possible shift in the process when nine or more consecutive points align on one side of the centerline.

- Rule 3: Detects cyclical patterns within the process, triggered by six or more consecutive points alternating in direction.

- Rule 4: Signals a potential trend in the process when four or more consecutive points cluster on either side of the centerline.

- Rule 5: Suggests a shift in the process with two out of three or more consecutive points lying on one side of the centerline.

- Rule 6: Identifies non-random patterns in the process, characterized by four or more consecutive points deviating from a straight line.

Empowering Food Safety with Presage Analytics

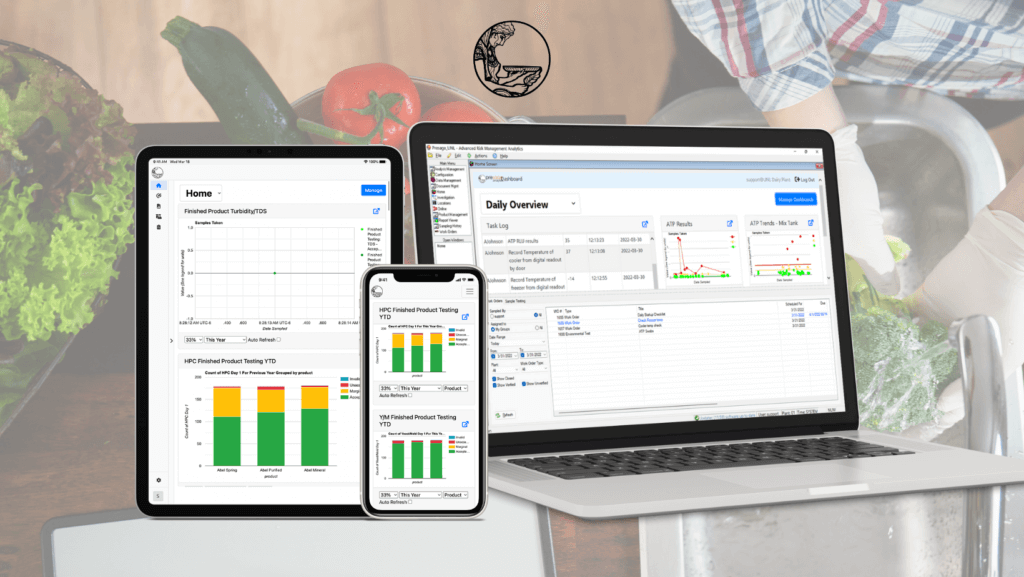

Presage Analytics leverages the potency of SPC and WECO rules to offer real-time insights into process dynamics. Our platform provides instant feedback, alerting users to deviations from expected process behavior, even when parameters ostensibly fall within conformance standards.

The significance of SPC extends beyond proactive monitoring; it serves as a retrospective tool as well. With Presage, users can meticulously evaluate the impact of process modifications on outcomes. This retrospective analysis facilitates informed decision-making, enabling businesses to fine-tune processes for enhanced consistency and quality.

Schedule A Demo Today

With Presage Analytics, your journey towards fortified food safety protocols begins. By embracing SPC powered by WECO rules, you gain a proactive stance in safeguarding product integrity and brand reputation.

Don’t wait for issues to arise; take charge of your processes today. Schedule a demo with our team to explore firsthand how Presage Analytics can revolutionize your approach to food safety and compliance. Let’s embark on this transformative journey together, ensuring your products meet the highest standards of quality and safety.