Better Work Order Management

Missed checks or delayed actions can lead to serious compliance issues and product quality concerns. Every task counts, which is why effective work order Management is essential.

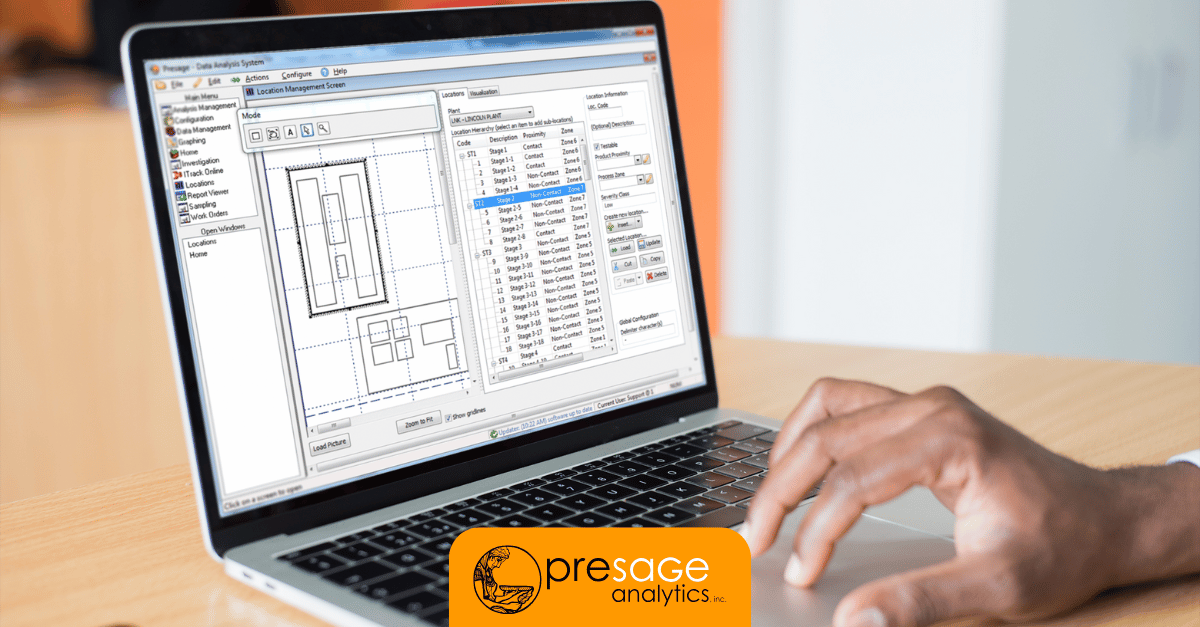

Work orders organize your team’s daily responsibilities. They ensure critical tasks, such as production checks, sanitation routines, and environmental monitoring, happen on time and are properly documented. For companies looking to modernize and strengthen their FSQA processes, software with smart work order systems, like Presage Analytics, can make a major difference.

Why Work Order Management Matters in Food Safety

Traditional methods like paper logs and spreadsheets slow teams down. They create confusion, make records harder to track, and open the door to human error. These issues can lead to audit failures, poor traceability, and reactive problem solving.

By moving to a digital work order Management system, teams gain real-time visibility, centralized control, and consistent execution of routine and critical tasks. That translates to better data, faster responses, and stronger compliance.

Key Benefits of Digital Work Order Management

Implementing a digital work order system supports more efficient, compliant operations across your facility. Here’s how you can benefit:

- Centralized Task Assignment: Supervisors can easily assign tasks based on roles, shifts, or specific zones in the plant. Teams know exactly what needs to be done and when.

- Improved Data Collection at the Source: Instead of writing notes on paper, technicians enter results directly into mobile devices while on the floor. This speeds up data entry and cuts down on errors.

- Automation of Recurring Work Orders: Tasks that happen daily, weekly, or monthly can be scheduled automatically. This ensures nothing slips through the cracks, even during staffing changes or busy seasons.

- Real-Time Tracking and Alerts: Custom alerts help your team stay on top of upcoming or overdue tasks. Managers can see the status of all active work orders from one dashboard.

- Customizable Work Order Types: Whether the task involves a production line, sanitation process, or environmental sampling, work orders can be tailored to suit your facility’s needs.

Support Compliance with Better Oversight

A well-organized work order management system doesn’t just make daily work easier, it also helps you stay audit-ready. When data is organized, searchable, and time-stamped, demonstrating compliance becomes much simpler.

Digital work orders also make approvals and reviews faster. Supervisors can verify completed tasks and escalate issues when needed, all within the system. You can even generate reports that summarize task completion, sampling results, and corrective actions.

Boost Efficiency and Focus

Automating routine tasks allows FSQA teams to focus on what matters: accurate data entry, meaningful observations, and continuous improvement. With fewer distractions and better organization, technicians spend more time doing quality work—and managers spend more time analyzing trends and solving problems.

See Work Order Management in Action

If you’re ready to reduce paperwork, improve task oversight, and strengthen your food safety processes, now is the time to explore how a better work order management system fits into your operation.

Presage Analytics offers a powerful, flexible solution designed for food, beverage, and manufacturing companies. To see how it works, schedule a demo with our team today.